12 for maximum dynamic capacity using real-coded genetic algorithms and. To increase the life of cylindrical roller bearings the profile or the crowning of the roller plays an important role.

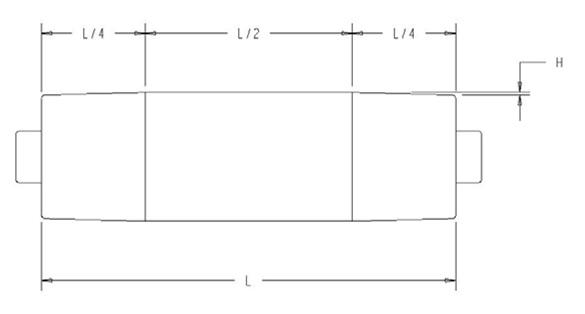

A crowned roller is a drive drum with a cylindrical center section with a tapered section on each end.

. In order to produce a centering influence on the belt a crowned pulley is designed with end diameters that are smaller than the pulleys central diameter. As a general rule only as many pulleys and rollers should be installed as are necessary to carry and guide the belt. Each pulley and roller can be the cause for belt running problems as well as for accumulation of debris.

The amount of crown barrel shape is calculated from beam deflection formulas. The long fatigue life is the one of the most important criterion for the design of rolling bearings however due to complex and diverse internal geometries each type of rolling bearings require a different design formulation. Crowned rollers have a slight curve.

The shape of a crown is nominally the shape of a beam deflected under a uniformly distributed load as shown in Figure 3. A crowned roller is a drive drum with a cylindrical center section with 2 tapered sections on each end. Slotted mounts are suitable for less heavily loaded rollers eg.

Also known as cam followers track rollers support loads while guiding and positioning work. For pivotable carrying rollers. Crowned Races in contradistinction to conical races would function with less scuffing in rollerrace contact areas.

The length of the tapered section s are generally ½ the length of the cylindrical center section. The amount of crown needed usually is very small and within a magnitude of a few mils 0001 in. In a crossed-roller bearing the races are conical surfaces at angles of 45 to the axis of rotation.

MadeWell Crown Rollers can be used in conjunction with DualVee Guide Wheels for applications requiring pairs of linear guide systems operating in parallel. All rollers have end seals to block dirt and contamination. The length of the tapered section is generally ½ the length of the cylindrical center section.

Adjustment is still recommended to tune in the crowned roller due to compensating for production tolerances of the conveyor and the belt. The tracking methods work by using the tapered ends in order to steer the belt back to the center. This creates tapered surfaces on which the belt moves which push its edges towards the center of the pulley.

The crossed-roller bearing design is the roller equivalent of the x-type ball bearing design. Such arrangements are used when wide spans or high moment loads need to be supported. It is compatible with most of the belt types It can also be used on nose bar transfers.

Designed to run on flat surfaces or in C channel track the uses are limited only by your imagination. Below we have listed some pros and cons of the crowned pulley. The different diameters also produce different circumferences around the pulley.

A crowned spreader roll has an arced surface across its face with the arc sweeping from the ends out toward the center of the roll face. Crowned pulley comes with tapered ends and cylindrical middle section. Because they never need to be relubricated these rollers are a good choice for hard-to-reach places.

Adjustment is still recommended to tune in the crowned roller due to compensate for production tolerances of the conveyor and the belt. The optimization of cylindrical roller bearings was first tackled by Kumar et al. The ends of the roll face are the smallest.

Roller linear guide roller crowning finite element analysis structure improved design Introduction Roller linear guide has the advantages of high rigidity high stability of accuracy and stable operation compared to ball linear guide pair. It is widely used in high-speed numerical control NC machine and machining center. Thread the stud directly into a component or secure with a nut for through-hole mounting.

![]()

Linear Guides In Motion Design Pbc Linear Europe Gmbh

Crowning Data For Conveyor Belt Rollers Splawn Belting

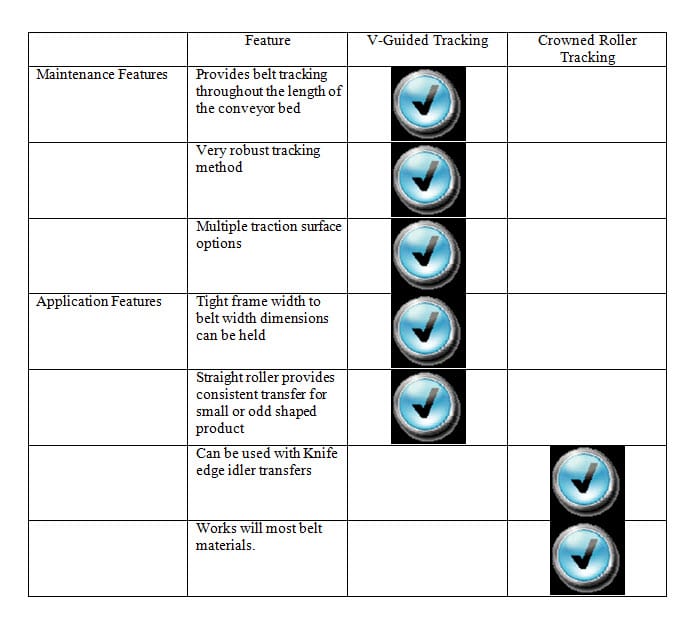

Belt Conveyor Tracking V Guided Vs Crowned Roller Dorner Conveyors

Pin On Sliding Bicycle Storage

Belt Conveyor Tracking V Guided Vs Crowned Roller Dorner Conveyors

0 comments

Post a Comment